Presentation

The Testing laboratory of internal combustion engines that work on biofuels is located in building D, room D13 and is dedicated to high level research.

Responsible: prof.phd.eng. Nicolae BURNETE

Tel. 0040 264 401 700; Fax. 0040 264 415 486

E-mail: Nicolae.Burnete@auto.utcluj.ro

The Testing laboratory of internal combustion engines that work on biofuels is located in building D, room D13 and is dedicated to high level research.

The Testing laboratory of internal combustion engines that work on biofuels TESTECOCEL is a latest generation facility (unique in SE Europe), TUV and RAR approved.

The Testing laboratory of internal combustion engines that work on biofuels TESTECOCEL is dedicated to high level research for:

- Masters cycle

- PhD studies

- Research contracts

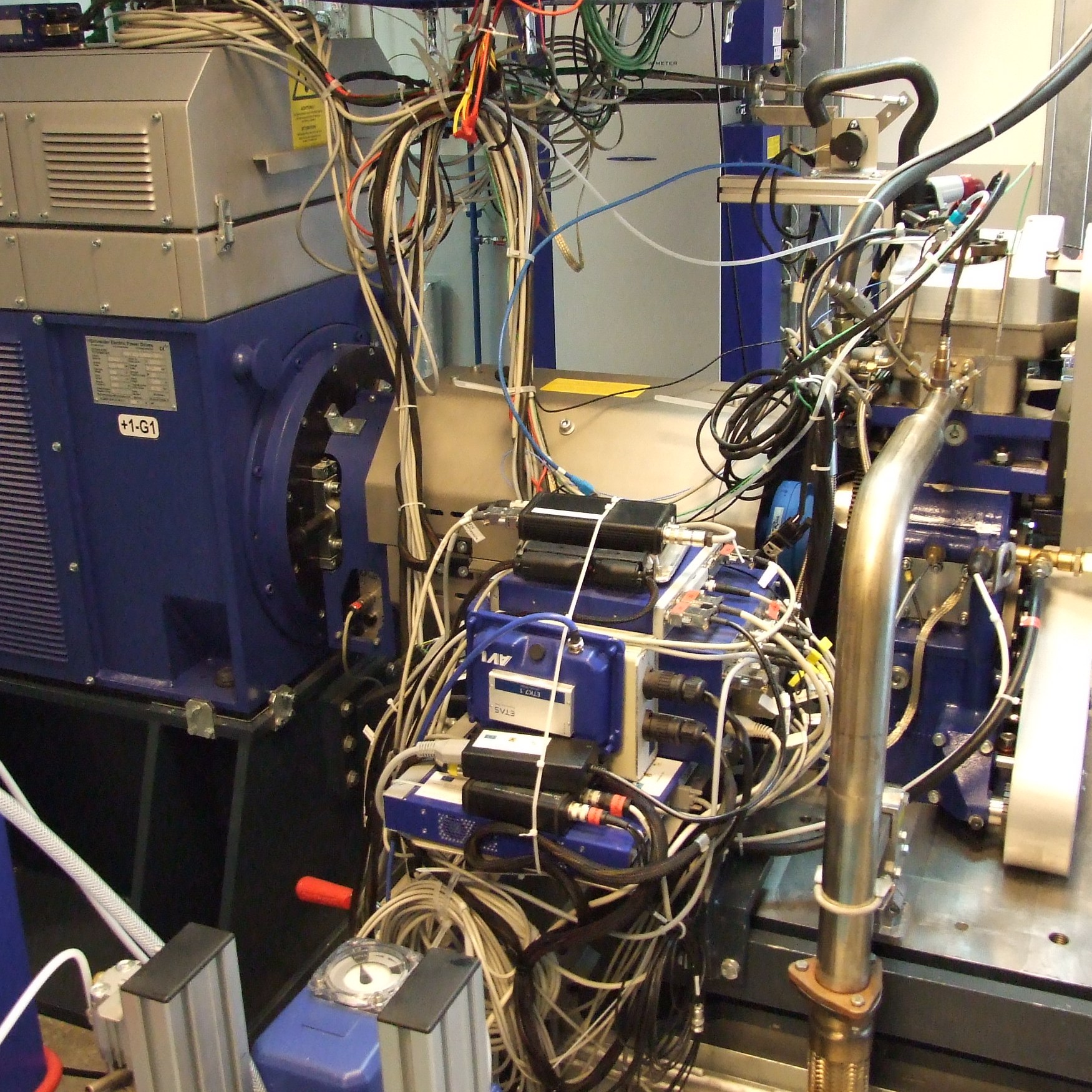

- Engine testing: in the Laboratory, different types of tests can be performed, like engine functional analysus, reliability studies and dynamic testing (transient cycles) on internal combustion engines that work on conventional and non conventional fuels.

- Fuels testing (working on engines): analysis of the main physical and chemical properties of fuels used as power source for internal combustion engines, and full emissions analysis.

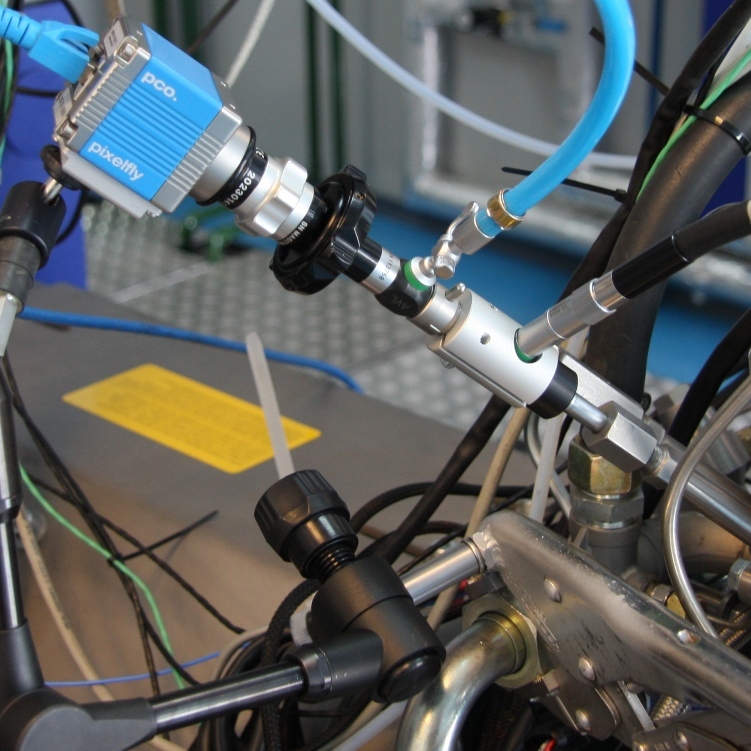

- Optical analysis of the in-cylinder burn process: using endoscopic cameras and transparent components of the engine, the phenomena inside the combustion chamber can be analyzed, like the flame velocity and propagation for different fuels.

- Active dynamometer that works as a starter for single cylinder engines and then as a load, it can go to speeds up to 12.000 rpm, a torque of 540 Nm and powers of up to 220 kW.

- Single cylinder research engine with three kits: direct and indirect injection gasoline engine kit, transparent engine kit (gasoline) and direct injection Diesel kit.

- Open ECU (Electronic Control Unit) that allows the injection maps to be adjusted for different fuels. For the Diesel kit, 4 injection sequences can be performed, with control over timing, quantity and density of the fuel.

- Cold chamber: allows cooling of the engine down to - 30 C, for startup tests.

- Emission Detector that allows the analysis of up to 35 chemical compounds depending on the fuel: diesel, gasoline, ethanol, biodiesel.

- Conditioning/Ventilation system that maintains a constant temperature inside the test chamber (for standard tests).

© 2016 DART